Airports Are Built to Keep Moving

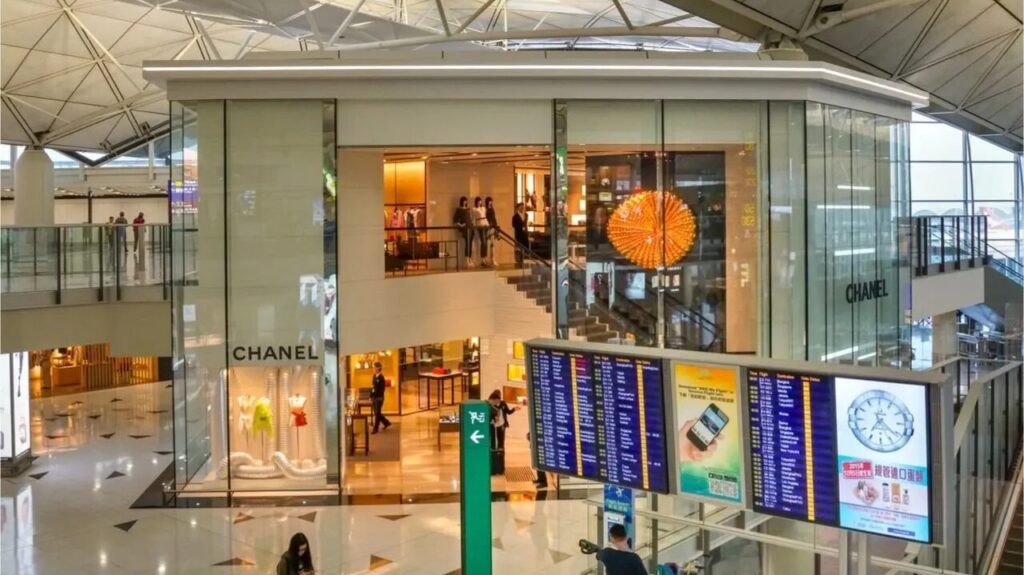

Major hubs like Singapore Changi Airport regularly handle more than 67 million passenger movements a year, while Hong Kong International Airport sees upward of 53 million passengers annually. Construction takes place alongside this constant flow of passengers, with staff working across multiple shifts and security operations that remain active at all times. There is no clean separation between building works and daily operations, which makes every intervention high risk.

In this setting, airport construction projects unfold within tight operational constraints. Access windows are limited and often shift. Noise and dust controls are non-negotiable, while security protocols govern how people and equipment move through the terminal. Any lapse can affect passenger flow or compromise safety, which is why disruption has to be avoided.

Consequently, airport construction is about building in a way that blends into the background of a working terminal. This shift in approach is significant and it separates airport work from most other forms of construction. Sequencing becomes more important than speed, and planning carries more weight than compressed timelines.

How TCG Adapts to Live Airport Environments

The conditions outlined above shape every decision made on site, particularly in live terminals where works unfold alongside ongoing operations. Our experience delivering airport fit-out projects across Singapore and Hong Kong has reinforced a clear understanding of how live terminals operate, from restricted access windows and security clearance requirements to daily programme adjustments driven by flight schedules.

Working inside live environments means accepting that construction logic has to bend to operational priorities, with buildability assessed against passenger movement, programme decisions shaped by security protocols, and planning grounded in how the airport functions day to day.

This mindset carries across our wider airport construction projects. Whether delivering refurbishment works or upgrading operational spaces, our role is to support continuity first and build second. That principle guides how we plan, coordinate, and deliver across different regulatory and operational contexts.

Working Inside Hong Kong International Airport

Our work at Hong Kong International Airport sits within a long-term, multi-project environment. Over time, we have supported different parts of the airport’s operational ecosystem, responding to changing needs while working within the same operational and security constraints expected of a major international hub.

Completed projects include the upgrade of terminal training facilities spanning 4,500 sq ft, as well as the refurbishment of executive meeting and decision-making spaces covering 2,691 sq ft. In both cases, works were delivered within operational airport facilities, where security protocols and day-to-day functions continued throughout the programme.

Alongside these completed works, we are currently engaged on additional enhancement projects within the airport estate, involving operational and ancillary buildings totalling over 10,000 sq ft across multiple programmes. These ongoing works extend into broader operational upgrades, reinforcing our role within airport construction Hong Kong as a trusted delivery partner. The ability to return to the same airport environment, under consistent operational expectations, signals confidence in how we coordinate and manage risk.

Working Inside Singapore Airlines’ New First Class SilverKris Lounge

Working within a live terminal introduced a dual challenge. Every activity had to meet the airline’s expectations while complying with airport safety and security requirements. Tight working windows for demolition and noisy works, controlled logistics, and constant coordination were essential to maintaining flow in a space that never truly sleeps.

Delivering the First Class SilverKris Lounge refurbishment at Singapore Changi Airport Terminal 2 meant working within one of the world’s busiest transit hubs. Naturally every activity, from material delivery to on-site coordination, had to take place amid constant passenger movement and heightened security.

Unlike a standard interior fit-out, work in live construction environments offers no margin for disruption. With restricted access and limited working hours for noisy works, schedules were adjusted daily to align with terminal operations, ensuring continuous comfort for both travellers and staff.

While the environments in Hong Kong and Singapore differ in governance and exposure to passengers, the underlying challenges are remarkably similar. Delivery is shaped by how the airport functions day to day. Whether the work involves airport refurbishment within operational buildings in Hong Kong or a live airport fit-out in Singapore, the need for close coordination and adaptability remains constant.

What links these projects is a consistent way of working that carries across both markets. Planning is grounded in operational reality, with sequencing developed through close coordination with airport authorities, airline teams, and consultants. While regulations and approval processes differ, the underlying mindset remains the same. This consistency allows us to move between jurisdictions and underpins long-term partnerships, where trust is on repeat delivery under the same constraints.

We continue to work closely with consultants and partners who share an understanding of what it takes to deliver within live airport environments.